ELECTRIC, WITH AN EDGE

One of the most common transformers nowadays are pole-mounted transformers, and there are numerous pole-mounted transformer sizes in the market today, but which single-phase pole-mounted transformer size or three-phase pole-mounted transformer size should you choose?

Keep in mind that each size has a different pole-mounted transformer price.

This is all the more the reason why it is important to know more about them to make the best pole-mounted transformer purchase decision.

With that in mind, DAELIM, a company that has been manufacturing pole-mounted transformers since the early 2000s, will help you make the best purchase decision.

But first and foremost, it is crucial that you know what are the basics or fundamentals of pole-mounted transformers so that you will not get confused along the way as you look into the different pole-mounted transformer sizes.

Whether if your purpose of purchasing a pole-mounted transformer is for business or crypto mining purposes, it is highly recommended that you get the correct specifications for your transformer in order to fulfill the needs of your business or bitcoin mining farm projects.

2021 Ultimate Single Phase Pole Mounted Distribution Transformer Guide

-This article describes Single Phase Pole Mounted Distribution Transformers in detail. Help your transformer purchase.

2021 Ultimate Three-Phase Pole Mounted Transformer Guide

-Are you looking for a powerful, portable, easy-to-use Three-Phase Pole Mounted Transformer that can be mounted on a pole?

The Complete Guide to Telephone Pole Transformer

-This does not affect telephone pole transformers since telephone pole transformers have a lot of purposes. Check it more!

No matter what the pole-mounted transformer size is, it is expected that the way the pole-mounted transformer works is that the four terminals that you see on a pole-mounted transformer represent the secondary connections

Basically, the one that is on the furthest left goes to one end of the secondary, while the one on the furthest right goes to the other end.

The center one is tapped on the secondary and is expected to become the wire to the panel and is grounded.

The lower one is the ground, which is going to the outside of the enclosure.

At the bottom of the enclosure, you will see a connection in which all of the pole grounds are tied together.

From a certain angle of view, you will be able to see that one of them will go to the guy wire that is responsible for holding the wire that is going to the house.

That particular wire will then be considered as the neutral wire to the panel.

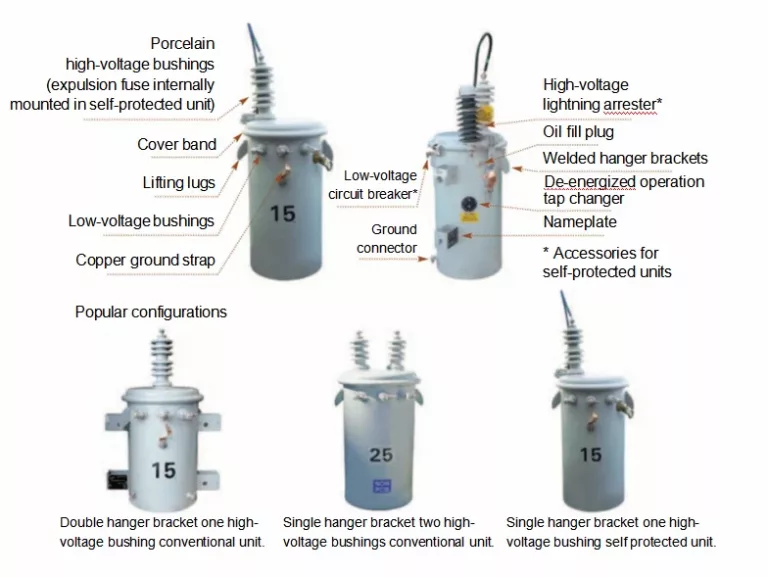

From a certain angle, you will the high voltage where the high voltage enters the transformer through its insulated bushing or what is also known as a “high voltage bushing”.

The additional bushing on the right is called a “Lightning arrestor” and this is only for pole-top transformers.

The lightning arrestor is also attached to the enclosure of the transformer and it settles beside the transformer’s primary bushing.

This, therefore, represents the ground.

This means that any energy on the line will jump that spark gap, directly go to the ground.

The purpose of this is to secure or protect the transformer from damages.

Although the transformer does well under minimal supervision, the spike is often passed through that can reek of havoc with sensitive electronics in the house.

The lower wire that comes from the utility is expected to be grounded on the pole.

Although it is on-ground potential, the wire will carry all the current at the house’s use.

If the house’s maximum is 200 amperes, then the current flow in the wire will be 60 amperes to make it compatible due to the transformer action (If you have a 30:1 step-down transformer).

In the case that the wire is broken, even though it is grounded, the reconnection is expected to show a spark.

If the circuit is being energized in any way.

Never allow yourself to get physical contact with the circuit whatsoever as this can cause life-threatening risks.

Keep in mind that the highest wire coming from the insulator is known as that “Power Wire”, and as you follow that wire down, it is connected to the top of the primary winding that is inside the transformer’s enclosure or body.

To begin with, this process is applicable to all single-phase pole-mounted transformer sizes.

To see what is inside a pole-mounted transformer, you must carefully remove the nuts and bolts that are holding the primary bushing into the enclosure of the single-phase pole-mounted transformer.

The most common wrench being used to remove the bolts and nuts of a single-phase pole-mounted transformer are 17 millimeter and 19-millimeter wrenches.

Start from the top of the bushing and then remove all the nuts that are holding the flange assembly together.

Afterward, proceed on removing the rubber gasket on top of the single-phase pole-mounted transformer.

Then carefully remove the flange assembly from the enclosure of the transformer.

Make sure you place it in an area that you are not going to step into to avoid causing damages to the transformer’s flange assembly.

You can then remove the bushing to expose the primary copper conductor that is expected to be wrapped in a paper insulation cover.

You will then see the primary terminal that is associated with a primary copper conductor wire that is also wrapped with paper insulation.

Moreover, you will need to remove the latches of the enclosure to expose the internal components of the single-phase pole-mounted transformer.

There are usually 6 latches on the enclosure but some single-phase pole-mounted transformers can have more or less depending on the manufacturer.

After removing the latches, you then carefully remove the cover of the single-phase pole-mounted transformer.

Now that you have successfully opened the single-phase pole-mounted transformer, you will then see all the exposed components, but what are these components exactly?

First and foremost, before you remove the latches of the single-phase pole-mounted transformer, you will see a yellow ring on it, and this is what is known or called as a:

The yellow ring that you will see after removing the bushing is called the “Seal Gasket”.

But the first thing that you would see once you remove the lid of the enclosure is transformer oil or mineral oil submerging all the components.

The oil is used for the transformer is used to cool down or regulate the temperatures of the transformer while it is operating.

Aside from the primary bushings, there are three other bushings that are significantly smaller than the primary one, and these are called “Secondary Bushings”, which are low-voltage bushings with a common neutral in the center of them.

Each of the secondary bushings is connected to the main breaker.

The secondary bushing goes to a specific point of the primary windings, and you can see the complete wirings deep beneath the transformer.

Underneath all that oil you see is a breaker, The breaker is a protective device that keeps the entire transformer protected from faults, short circuits, and other electrical interruptions that can potentially destroy the transformer along with its internal components.

The power breaker is responsible for breaking the secondary circuit.

The tap changer’s function is to regulate the voltage that is according to the turn ratio that is inside the primary winding.

Since pole-mounted transformers are public transformers, no matter what the pole-mounted transformer size is, it is without a doubt that these transformers can be seen almost everywhere we go outdoors.

People often take for granted the big role they play in our electricity consumption.

Basically, the main function of a pole-mounted transformer is to transform or change the voltage from high electrical power lines to a lower voltage that is compatible with everyday home use.

This goes to say that without these devices, raw electrical power would totally be useless to everyday electrical consumers including you.

And no matter what time frame it is, transformers are considered a critical part of our lives.

To build a transformer, pole-mounted transformer manufacturers start with taking paper that is coated with epoxy glue and taping it to a wooden block.

The next component would be to take a ⅛” thick aluminum strip, which is a metal that is capable of withstanding high temperatures that high voltage currents commonly produce.

As the block is being rotated, the paper and the aluminum strip will be wrapped around it, and an aluminum bus bar that is also called the “low voltage lead” will be responsible for sending low voltage current out from the transformer.

The manufacturers will then fold the lead and transfer the unit to another block that is rotating for more wrapping.

The insulating paper consists of epoxy glue that is on both sides that will melt the glue and bond several components in place.

On the next block, The manufacturers will then add the insulating paper along with the epoxy-coated wire.

The result of this will then cover the paper then repeat the entire process that will form the second layer of copper wire.

The next step would be to heat a high voltage lead to the copper wire, then roll out another set of copper wires.

The manufacturers will then weld the lead wire that will protrude from the transformer’s cylinder, and attach it to the vinyl coated wires that are connected to different kinds of voltages out of the transformer.

The completed unit is known as a “coil”, and with the use of electrical steel, manufacturers will then proceed on building the main components of the transformer, which is called the “core” and these parts mentioned are available on all pole-mounted transformer sizes including single-phase pole-mounted transformer sizes and three-phase pole-mounted transformer sizes.

The coil and core is expected to be secured with a metal strapping that ensures the transformer to fix the assembly that is in the tank.

The parts will then be placed inside a heater or transformer oven to be baked for 8 hours at 275 degrees.

The heat will be responsible for enhancing the insulation by removing traces of humidity because the presence of humidity can complicate the entire transformer.

Furthermore, inside the heater or oven, this will melt the epoxy glue that will fuse together the paper and aluminum strip, and the copper wires as well.

The assembly will then proceed to a steel tank, while a rubber gasket is being hammered into the top of the enclosure.

Moreover, a grounding wire will be bolted inside the enclosure.

There will be three thermoplastic bushings inserted into the low voltage lead, which will be bolted into the tank as well.

Afterward, manufacturers will adhere an oil filling guide to the tank.

The usual placement of the guide will be on the side of the transformer.

There will then be an automated filling machine that is responsible for filling the entire transformer with transformer oil or mineral oil.

This machine draws a vacuum to ensure that the device will be properly dispersed all throughout the coil.

As mentioned, the purpose of submerging the components of transformer oil or mineral oil is for thermal and insulating purposes.

Now that the transformer is almost completely built, manufacturers will then add a fault detector to the transformer to alert the manufacturers or operators that if there is a short circuit.

A worker will then place a lead wire through the thermoplastic bushing and secure it in place.

Now that the tank is bolted shut after installing the high voltage connector, the transformation is then considered as a finished product.

Before transformers are being placed in the market, all pole-mounted transformer sizes will undergo numerous electric tests to ensure that the transformer is ready to be used for public use.

When it comes to the different single-phase pole mounted transformer sizes, there are plenty of options available out there and if your purpose of purchasing one is for your crypto farm, then it is expected that it will require a lot of power for your mining rigs to function and operate all throughout the day.

So, if you are looking for a certain single-phase pole-mounted transformer size, then I highly recommend that you contact DAELIM to get the appropriate size of your choice.

In the case that you prefer a certain three-phase pole-mounted transformer size, then it this setup is without a doubt good for bitcoin, ethereum, or other cryptocurrency mining projects because three-phase pole-mounted transforms can be better compared to single-phase pole-mounted transformers.

But if you are unsure of which one is best for your setup, then do not hesitate to contact DAELIM for professional advice for which electrical device you should get for your crypto mining project.

After filling in the contact information, you can download the PDF.