How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

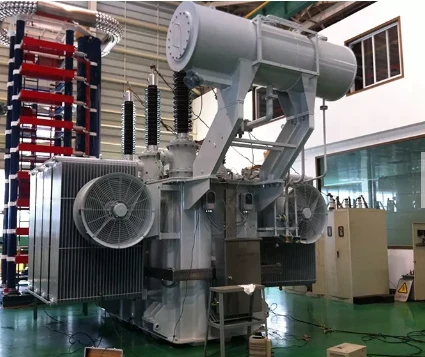

A 220kv transformer belongs to the critical transmission equipment in the power system. It plays the role of hub position, whether the transformer is reliable, for the power system safety and reliability to produce a direct impact. For a 220 kV transformer, many factors often lead to failure, such as installation, manufacturing, transportation, etc., which can impact the power system’s transmission capacity and can lead to large-scale power outages in the power system. This paper gradually analyzes the failure rate characteristics of 220k V transformers to provide a valuable reference for practical work.220kv transformer

220kv transformer is a more common transformer.Throughout the practical experience, as well as the joint review of relevant literature, and analysis, for the study of transformer failure, transformers appear unscheduled outages, especially forced outages appear fault parts to start. In the 220kV voltage level of the transformer, many aspects can produce fault problems; the occurrence rate is relatively high in the coil, bushing, core, insulation medium, cooling device, voltage regulator, the Neutral point equipment, oil pillow, etc.

The Institute of Electric Power Research (IEPR) has conducted a statistical survey of 220kV transformer defects for 2010-2020. The results show that the components that frequently fail in transformer operation are mainly the cooling system’s cooler, tap changer, bushing, and oil conservator. By classifying the severity of various transformer faults, the windings and cores play a vital role in the regular and stable operation of 220 kV transformers.

The analysis of 220 kV transformer faults is a crucial basis for the reliable design, manufacture, testing, and operation of transformers. It can generally be carried out by constructing a transformer fault tree model, a step-by-step classification of 220 kV transformer faults into basic fault types, thus forming a transformer fault tree. During the construction of the 220kV transformer fault tree, the top event is the fault situation threatening the safe operation of large transformers. It requires urgent maintenance, and the intermediate event is the event that triggers the ultimate event.

Read on power transformer low loss manufacturer price

Winding faults appear in the transformer coils, longitudinal insulation, and segments. Winding responsibilities can be divided into several main fault modes: winding disconnection, winding inter-turn short circuit, and winding high temperature overheating. The winding fault has a more significant degree of severity than a transformer fault, generated by factors such as incorporating own structure and insulation unreasonable. And winding short circuit belongs to a higher incidence of winding failure, and produces a heavier degree of impact, will affect the core, lead, insulation layer, and so on.

The regular operation of a 220kV transformer is closely related to the quality of the core and winding, which are the critical components for electromagnetic energy transfer and exchange. A lot of accumulated practical experience shows that faults in the magnetic circuit are always high, i.e., in the core, yoke, and clamping elements of the power 220 kV transformer. Local overheating and suspension discharge are among the main failure modes. Multi-point grounding of the core, local short circuit of the center, and poor heat dissipation and magnetic saturation can lead to local overheating problems; fused ground lug and poor grounding can lead to suspension discharge problems.

The transformer oil, insulating paper, board, and insulating parts in the insulation system constitute the failure rate characteristic analysis of the 220kV transformer.

At the same time, insulation failure modes include insulation damage and dielectric loss overload. In case of insulation fault in transformer, for a short time, it can be operated normally, but it will cause problems such as partial discharge and mild overheating inside. If the time of fault is increased, it will lead to aggravating the phenomenon of insulation damage, which in turn will cause defects such as local short circuits in winding and carbonization of insulation parts inside the 220kV transformer.

In a 220kV transformer, the lead belongs to the more fragile but critical components, belongs to the internal winding out of the line, and the external wiring of the intermediate link, the joint is welded. Insulation wrapping deals with the outside of the lead to avoid poor contact and short circuit problems, so the effect of welding and insulation state will significantly impact the lead failure.

The factors of lead failure are lead short circuit, lead break, lead poor contact.

Lead phase short circuit for a fatal fault, not timely handling, will lead to winding phase short circuit, expanding the accident later aggravated into a catastrophic failure, and even lead to power transformer of 220 kV out of service.

The casing is a critical protection device for the winding of the 220 kV transformer and the external linkage lead of the tank. It is easy to produce insulation aging, enamel cracking, and other problems due to external factors, such as wind, rain, snow, electric field, pollution, etc… It belongs to the transformer’s high incidence of fault location.

Casing blowout, causing displacement, partial discharge, and open welding are common types of faults.

The tap changer is subjected to the influence of insulating oil and high temperatures for a more extended period, making the surface of the contacts susceptible to surface oxidation, which significantly increases the contact resistance between the contacts and results in poor communication. Once the poor contact situation occurs, it will lead to a high local temperature state, and the contact surface constitutes apparent damage.

The tap changer has many failure modes, typical of which are simplified explosion, misalignment of the gear sequence, gear damage, and contact burnout.

From the above, it can be seen that the fault of a 220 kV power transformer can be divided into various types according to the faulty parts. Still, in general, it can be divided into two categories: external faults such as leakage or damage of parts in power 220 kV transformer can be judged by direct observation, but internal faults need to apply tests for But internal faults need to be analyzed in depth by using tests to determine them.

At this stage, three methods are used to diagnose and analyze the internal faults of 220 kV transformers: visual judgment, power testing, and outage test. The three methods have specific correlations and backward and forward procedures.

After discovering the fault of the power transformer of 220 kV, the relevant operation and maintenance personnel should first inspect the site to generate intuitive judgment and report the abnormal situation of the transformer. After accepting the analysis of the bizarre reporting situation, the inspection and testing personnel can complete a variety of tests in the field of power 220 kV transformer without power environment, through this way of powered testing can determine whether there is a fault in the transformer and the general area of the fault site, further in-depth analysis, can clarify the 220 kV power transformer fault The nature of the fault and the severity of the fault can be defined.

To further determine the details of the transformer fault, the relevant operation and maintenance personnel can analyze and deal with the responsibility under the transformer outage test conditions when the transformer for the suspension of the construction of the environment is to clarify the abnormal fault parts and to explore the type of fault. In this specific situation, in this process, the operation and maintenance personnel can choose whether to apply an oil drain into the transformer to check according to actual needs.

Border operation and maintenance personnel in the process of daily inspection and check, if found 220kV transformer abnormalities, can apply intuitive judgment, the external situation of the transformer for detailed inspection, specifically through the observation of transformer appearance, 220kv transformer operation whether there is a strange sound, transformer temperature, and oil level situation of the transformer at this time to assess and judge the operating state If the initial judgment that there is a fault in the transformer, it is necessary to make clear the approximate scope of the responsibility, the specific type of fault and whether it is serious.

The current application rate of the high-speed charged detection technology is mainly for the oil in the gas detection, three ratio method, characteristic gas detection method, fault point temperature, and power judgment.

As one of the methods for detecting faults in oil-filled equipment, the three-ratio method mainly applies the three-pair ratio of five characteristic gases to determine and analyze the active faults of transformer equipment or reactor equipment.

In applying the triple ratio method, the three pairs of ratios with a consistent range of ratios can be shown by differential coding.

With the help of the power mentioned above testing method, the operation and maintenance personnel can confirm the existence of faults in the transformer and clarify the type of fault and whether it is serious. In some cases, the temperature and power of the fault point can be predicted by power testing.

The operation and maintenance personnel have clarified the type and severity of the transformer fault after the power-on test, so the primary assessment of the transformer fault has been formed before the outage test, but to further accurately observe the fault situation and carry out an in-depth analysis, the operation, and maintenance personnel can apply the outage test to the transformer if necessary, in the outage test process, in-depth analysis of the transformer fault type and fault situation, if The actual position requires can also transformer into the box to check.

Specifically, the outage test is helpful in further diagnosing and analyzing the fault condition of the transformer, and one or more tests can be targeted after the outage. The tests that can be applied include.

(1) voltage ratio measurement and coupling group marking verification

(2) application polarity test; (3) insulation resistance test

(3) insulation resistance testing; (4) measurement of dielectric loss factor and capacity

(4) measurement of dielectric loss factor and electric capacity

(5) detection of winding resistance

(6) the application of the core insulation test

(7) test the induced voltage and partial discharge

(8) application of external voltage withstand the test

(9) measurement of no-load loss and no-load current

(10) measurement of short-circuit impedance and load loss

(11) implementation of oil flow electrostatic detection (applied to forced oil circulation cooling mode)

(12) Performing temperature rise tests; (13) Monitoring load conditions

(13) monitoring load conditions; (14) implementing no-load inrush current detection

(14) implementation of no-load inrush current detection.

Using a practical case study approach, historical statistics of 220kV transformer failures in a region were observed, and it was found that a wide variety of causes (types) can lead to transformer failures and that the causes of transformer failures vary from one voltage level to another.

The number of 220kV transformer failures was 10, including two due to oil seepage from the heat sink, two due to severe oil seepage from the large cover, and trachoma. In addition, acetylene exceeds the standard, and material problems; acetylene exceeds the average. It is subject to short-circuit shock, submerged oil pump damage, casing contact overheating, acetylene exceeding the standard and internal turn-to-turn short circuit, and core grounding resistance reduction triggered by oil chromatography data failure, these failure causes transformer failure problems, respectively.

According to the statistical results, we can understand that the distribution of 220kV grade transformer fault causes is relatively scattered. Still, in the first year of operation, there are three fault problems, mainly heat sink oil seepage, acetylene exceeding the standard, and trachoma caused by the considerable cover oil seepage these fault factors. It is obvious to observe that the central aspect of these problems is the substandard quality.

According to the time of failure of the 220kV transformer, the statistics and the curve of failure rate vs. years of operation are plotted, and the corresponding curve fitting process is implemented. Figure 1 below shows the raw data and the fitted curve after the statistics. The graph shows that 220kV transformer failures occur in the first year and after ten years.

The main factor of the failure problem in the first year is the quality of the transformer itself, including oil leakage and material issues. After ten years, the failure problem is caused by insulation damage in many cases, thus completing the emergence of similar problems such as short circuits.

In the process of applying power transformers, due to a variety of factors still exist, some problems need to be solved; these still unresolved problems can lead to transformer failure or affect the operation, so the relevant staff of the power system must strengthen the inspection of transformer equipment, through the observation of the transformer’s use of the operating state intuitive judgment transformer whether there is a running fault, to ensure that the transformer in the process of operation With a better functional effect, to promote the power system can be more safe and stable operation.

Based on this paper, we analyze the causes of 220kV transformer failure and its failure rate, and we can understand that the first three years of operation and ten years later belong to the period of high failure rate. In the first three years of operation, the failures are mainly caused by material and process failure. After ten years of operation, the losses are caused primarily by insulation damage and improper maintenance.

By mastering the factors that cause failures, we can find scientific measures to reduce the failure rate of 220kV transformers and maintain the stable operation of the power system.

To reduce the failure rate of transformers in the first three years of operation, we need to work with transformer manufacturers to strictly control the material and process of transformers to ensure the quality of the network operation process. Before the official commissioning, maintenance personnel should exactly check the 220kV transformers to see if there is damage to the insulation bushings and oil leakage, check the tap joints and bolts are tightened and implement the corresponding insulation Test, no-load and short-circuit test, etc., and only after all test items are qualified, can the transformer be officially used.

After the 220kV transformer has met the quality standards, the failure rate in the first three years will be significantly reduced. To reduce the failure rate in the future, strengthening the daily management and regular inspection is the focus, such as diligently checking the sound, the temperature is average, for the transformer dirt and impurities are regularly cleaned up to prevent flashover discharge and other problems

Download Resource

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

After filling in the contact information, you can download the PDF.