How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

ELECTRIC, WITH AN EDGE

Transformer oil plays the role of strengthening insulation, heat dissipation, anti-corrosion and arc extinguishing in the transformer. Due to the high quality requirements for transformer oil, strictly speaking, it is difficult to say whether the transformer oil is qualified without going through the withstand voltage test and simplified test. Transformers generally use good-quality mineral oil. In order to prevent fires, non-combustible synthetic insulating oils can also be used. In addition to immersing the transformer body and improving the winding insulation, the transformer oil also has a cooling effect to prevent temperature rise. Transformer oil must meet the following conditions:

(1) In order to have an insulating effect, the electric strength should be high;

(2) In order to play the role of convection cooling, the coefficient of thermal expansion of the oil should be large, and the viscosity should be small. In order to increase the heat dissipation, the specific heat should be large and the freezing point should be low;

(3) Chemically stable, no chemical reaction at high temperature.

The temperature of the oil in the oil-immersed transformer rises and falls as the load changes, and the oil continues to expand and contract, which makes the air in the transformer repeatedly enter and exit. Therefore, the moisture in the atmosphere will enter the oil, which will not only cause the electric resistance strength to be reduced, but also the oxygen in the air in contact with the oil surface will oxidize the oil, thereby forming mud-like deposits.

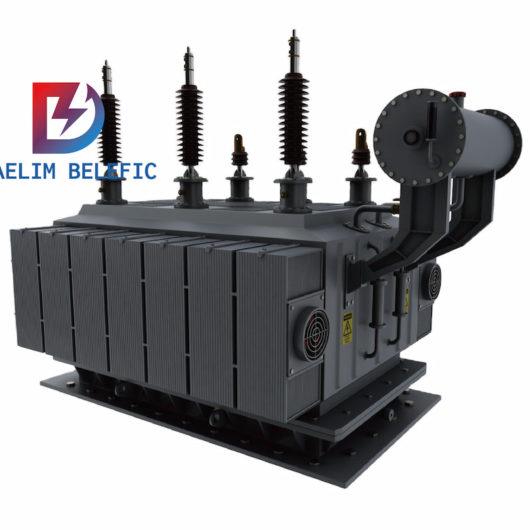

In order to prevent the above-mentioned oil deterioration, the oil storage tank shown in the figure (commonly known as the oil pillow-translator’s note) is used. The oil level changes caused by the expansion and contraction of the oil are only carried out in the oil storage tank. The oil pollution is reduced and the sediment is reduced. Can be discharged and cleared. In order to remove the moisture in the atmosphere, a glass hygroscopic respirator is installed on the oil storage tank, and an active aluminum alum hygroscopic agent is placed in it.

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

The primary function of the pad mounted transformer is to serve as a critical distribution transformer that steps down higher primary voltage from utility distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that converts high voltage electricity to lower, usable voltages for residential

When looking for the best pad-mounted transformer manufacturer, it’s important to find industry leaders known for reliability and innovative solutions. Pad-mounted transformers are essential in

After filling in the contact information, you can download the PDF.