ELECTRIC, WITH AN EDGE

Among the different pole-mounted transformer specifications are the three-phase pole-mounted transformer.

In this article, you will learn what a three-phase pole-mounted transformer is and how it works.

You will also learn about its advantages and why you may need one for your electrical power needs.

DAELIM is the world’s top professional transformer and electrical equipment manufacturer.

This top-performing company that manufactures electrical equipment has been a reliable and trusted brand for more than 15 years.

Following international standards like ANSI, IEEE, IEC, CSA, AS/NZ, etc., DAELIM upholds these standards with inexpensive and premium products.

14+FAQ ABOUT THE PAD MOUNTED TRANSFORMER

-What are Pad-mounted transformers? What inside a pad-mounted transformer?What are the pad-mounted transformer health risks?And How to choose a good Pad-mounted Manufacturer? Read on!

Electric Pole Transformer | Single Phase Transformer

-Learn the fundamentals of Electric Pole Transformers, including What is pole mounted distribution transformer, pole mounted transformer specifications, Read more.

A Complete Guide to Utility Electric Pole Transformer

-A Utility electric pole transformer is an electric utility distribution transformer mounted on a service pole. Check More.

Pole-mounted transformers are one kind of distribution transformer.

As the name suggests, these types of distribution transformers are installed on an electrical service pole.

Power poles are commonly made of wood or concrete.

You can often see poles and cables hanging over the street, where it sometimes runs along the side of a building.

The main purpose of these transformers is to convert high-voltage systems to a voltage level of either 120 or 240V.

Converted voltage levels are power sources used by end-users in homes and other small businesses.

Pole-mounted transformers are commonly seen in rural areas; they are smaller in size and mass compared to other distribution transformers.

These distribution transformers are inaccessible to animals and humans, which reduces the risk of injury and vandalism.

Aside from the reduced risk of injury and vandalism, these also do not take up much ground space because they are compact.

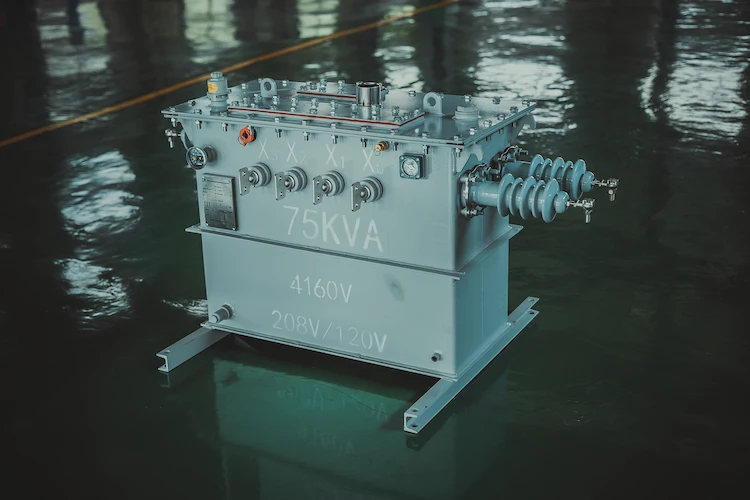

Three-phase transformers consist of three primary and three secondary coils represented as either 3-phase or 3ɸ.

This type of distribution transformer can be constructed in two ways.

First, it can be constructed by using three individual and identical single-phase transformers attached to a three-phase system.

The other way of construction is by building all parts of the three-phase transformer on a single core.

These transformers are mainly used to supply areas needing high voltage power, such as big industrial and commercial establishments.

A three-phase overhead transformer is an overhead transformer with a three-phase system.

It differs from other overhead transformers in the rating or sizes, applications, and installation.

Transformers all work to lower high-voltage power regardless of their variety and sizes.

A transformer has two sides which are the high-voltage and low-voltage sides.

When electricity flows, it enters the high-voltage side, where it travels around the coils of wire.

As it continues to flow, the magnetic field induces another voltage in the other coils.

Each coil of wire has a different number of turns based on how high or low the voltage is.

Coils on the high-voltage side will have more turns compared to the low-voltage side. Hence, transformation occurs.

Three-phase pole-mounted transformers have three forms of connections which are the:

The combination and configuration of the three windings on pole-mounted transformer connections depend on using the transformer.

Generally, the polyphase transformer is the term used to identify transformers providing three or more phases.

The following are the advantages of three-phase pole-mounted transformers over single-phase pole-mounted transformers:

A grounding wire is running down any electrical service pole.

The end of that grounding wire is attached in a coil to the base of the utility pole.

With this, you can observe that the grounding wire is in direct contact with Earth.

The wire runs 6 to 10 feet or 1.8 to 3 meters underground.

From the transformer, you will notice that two wires are running out of it. On the other hand, three wires are running to the house which is supplied by the transformer.

Two of these wires are insulated, while the remaining one is bare.

This bare wire is the ground wire.

The two insulated wires carry 120 volts each; they are 180 degrees out of phase. This makes the difference between them at 240 volts.

The arrangement of these wires allows homeowners to utilize both the 120V and 240V depending on their appliances.

Wirings of pole-mounted transformers are easier to understand through pole mounted transformer drawings and illustrations.

The main difference between three-phase and single-phase transformers is the number of windings on the sides of the transformers.

Single-phase transformers have two windings which are the primary and secondary windings.

On the other hand, three-phase transformers are composed of three windings or coils connected in the right sequence.

Proper sequencing of the three windings ensures that the three-phase transformer is in sync with the incoming voltage.

Single-phase transformers are mainly used to supply electrical power in smaller areas such as residential homes, light commercial loads, and different electrical appliances.

However, when supplying electrical appliances, single-phase transformers need side rectifiers.

Three-phase transformers supply high-voltage areas such as industrial establishments, large commercial areas, retail stores, factories, and other electrical appliances.

Certain requirements need to be followed when installing pole-mounted transformers. These requirements will ensure safety and minimize risks to injury or unfortunate accidents for the utility personnel. Below is the list of requirements:

1. When installing pole-mounted transformers, remember to install them close to where the load center is. This reduces line power drop and line voltage drop. Aside from that, make sure that the area where you plan to install the pole-mounted transformer is easily accessible in case maintenance and repair are required.

2. Take note of the following distances during transformer installation:

3. The height for all exposed charged objects on the transformer platform should be at least 3.5 meters.

4. Place warning signs at least 2.5 to 3 meters above the ground.

5. Avoid placing pole-mounted transformer stations in areas with flammable and explosive gases.

6. Place transformer stations near the unit that consumes the most electrical power.

7. The voltage drop should only be within the allowable range, especially for the furthest electrical equipment.

8. The low voltage line should always be below the high voltage line.

9.There should be a distance of 1.2 meters or greater between the high voltage and low voltage lines.

Without transformers utilizing electrical power, there will be no electricity to supply our appliances and other electrical needs.

We need to know the importance of these transformers and how they work in our daily lives.

Three-phase pole-mounted transformers are the transformers of choice when you need one that can supply larger establishments.

This type of distribution transformer is easy to assemble and install, cheaper, and highly efficient.

A suitable Three-Phase Pole Mounted Transformer manufacturer requires professional R&D capabilities and responsiveness.

You can check whether it is a factory in the business system of the country where it is located.

At the same time check the authenticity of his IEEE, ANSI, CSA, IEC certificates.

At Daelim, you are guaranteed safe, durable, and high-quality transformers.

These transformers are guaranteed their price worth that will certainly last for years to come.

If you find that the existing distribution transformer types or power cannot meet your requirements. You can choose to tell Daelim. Daelim has a team that has always had a wealth of design transformers, and can give you a specific design plan in the shortest time.

Daelim’s distribution transformers comply with IEEE, ANSI, CSA, IEC certification, and are used in North America (such as Canada, the United States, Mexico), South America (such as Ecuador, Chile), Europe (such as Spain, Lithuania) and some Asian countries. Daelim even has a professional installation team that can provide you with installation services.

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

After filling in the contact information, you can download the PDF.