How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

ELECTRIC, WITH AN EDGE

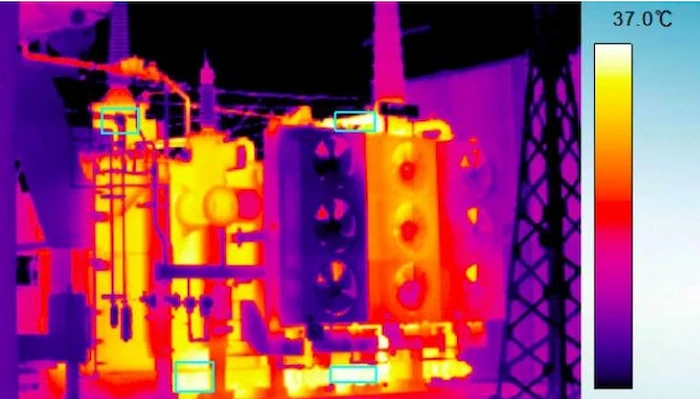

The stable operation of the transformer is the basic guarantee for the safe operation of the power grid. Through the analysis of abnormal operation data of the transformer and common failure of transformer.

This article mainly analyzes the causes of transformer oil leakage, transformer internal faults, abnormal transformer sound, abnormal transformer oil temperature, abnormal transformer oil level, abnormal external transformer, heat generation of transformer lead joints, and transformer cooling system failure.

Analyze eight common faults of transformers and propose solutions.

Provide technical support for the lean operation and inspection of power grid equipment, and eliminate potential safety hazards in power grid operation in a timely manner through state detection methods.

This is an advertisement: Daelim is a transformer manufacturing company with a history of 15 years. We can provide you with customized services. Purchasing our transformers, you will have an exclusive designer team and maintenance team. What are you waiting for

Due to manufacturing quality, installation process and other reasons, transformers often have oil infiltration, and in severe cases, they will gather into oil droplets and cause oil leakage.

Generally, it is stipulated that the infiltration point of oil stains is the leakage point, the dripping point of the oil droplets is the general leakage point, and one drop of oil every 5 min is a serious leakage point.

Transformer oil leakage mainly occurs at bolted joints, welds on the tank body, and flange joints.

(1) The valve is not closed tightly, the material of the rubber pad is poor, the accuracy of the drain valve is not high, and the pressure of the bolt connection is uneven.

(2) Cracks in the high-voltage bushings, loose sealing gaskets of the outlet pile heads of the current transformers on the foundation, broken small insulators, etc.

(3) The rubber pad remains elastic when compressed 2/3 after installation, but it is affected by factors such as oxidation, high and low temperature, vibration, etc. The rubber pad is easy to age, crack, and lose its elasticity, causing leaks due to inadequate sealing;

In addition, the asymmetry and eccentricity of the installation position of the rubber pad will also cause leaks due to inadequate sealing.

(4) The welding seam of the transformer body is blistered, rusted or damaged by external force.

When there are faults such as short-circuit between turns, insulation damage, poor contact, and multi-point grounding of the iron core inside the transformer, heavy gas protection will occur.

Abnormal accessory equipment causes the gas relay to operate.

One is that the respiratory system is not smooth.

When the transformer breathing system such as air bag respirator, on-load pressure regulating respirator, etc. is not smooth or blocked, it will cause gas protection action.

The second is air leakage in the cooling system.

When the cooling system is not tightly sealed and enters the air, or the newly put into operation transformer is not vacuum degassed, it will cause the action of the gas relay.

The third is that the inlet valve of the cooler is closed.

The clogging caused by the closing of the inlet valve of the cooler can also cause frequent actions of the gas relay.

Fourth, the oil inlet valve on the upper part of the radiator is closed.

The closing of the oil inlet valve on the upper part of the radiator will also cause frequent actions of the gas relay.

The fifth is the transformer air intake.

Most of the causes of light gas action are caused by transformer air intake.

The main reasons for the air intake are the aging and damage of the sealing gasket, the deformation of the flange joint surface, the air intake of the oil circulation system, the clogging of the filter of the submersible pump, and the air intake of the welding place.

The main reason for the light gas protection action of the newly installed transformer is caused by poor installation technology.

If there is no vacuum oil filling, improper installation of the gas relay, and the standing time of the transformer for less than 24 h after filling the oil, the gas protection action may be caused.

When the transformer is in normal operation, it should emit a uniform “buzzing” sound, which is caused by the electromagnetic force generated when the current passes through the transformer windings attracting the vibration of the silicon steel sheet and the transformer itself.

If uneven or other abnormal sound is produced, it is an abnormal sound.

(1) The sound of the transformer is louder than usual and the sound is even. Possible reasons:

First, when single-phase grounding, resonant overvoltage or high-order harmonics generated by the use of thyristor rectifiers occur in the power grid, the sound of the transformer will increase. When this occurs, it can be judged by combining the instructions of the voltmeter. ;

Second, when the transformer is overloaded, it will make a high and heavy “humming” sound. If the load of the transformer is found to exceed the allowable normal overload value, the transformer load should be reduced according to the regulations;

Third, when the system is short-circuited, the larger short-circuit current causes the transformer to emit larger and dull noise.

(2) Transformer noise. Vibration caused by the loosening of some parts of the transformer, if accompanied by a significant increase in the sound of the transformer, and there is no obvious abnormality in the current and voltage, it may be that the internal clamp or the screw that presses the iron core is loose, which will increase the vibration of the silicon steel sheet. Caused by.

(3) Transformer discharge sound.

Possible reasons:

One is the external discharge of the transformer. If you see a blue corona or spark near the transformer bushing at night or in rainy weather, accompanied by a “crack” discharge sound, it means that the porcelain is seriously dirty or the equipment line card is in poor contact.

The second is the internal discharge of the transformer. When the ungrounded parts inside the transformer discharge static electricity or discharge between turns of the coil, or discharge due to poor contact of the tap changer. At this time, the transformer should be further tested or disabled.

(4) Transformer popping sound. When the transformer makes a popping sound, it is mainly caused by insulation breakdown inside or on the transformer surface. The transformer should be stopped for inspection immediately.

(5) The sound of boiling water in the transformer. When the transformer has the sound of boiling water, the temperature changes sharply, and the oil level rises, it is caused by the short circuit of the transformer winding or the serious overheating caused by the poor contact of the tap switch. The transformer should be shut down for inspection immediately.

The oil temperature gauge indicates the top oil temperature of the transformer, and the temperature rise refers to the top oil temperature of the transformer minus the ambient temperature.

According to the operating specifications of oil-immersed transformers, the temperature rise during normal operation should not exceed 55 ℃, and the top oil temperature should generally not exceed 95 ℃.

If the top oil temperature exceeds 95 ℃, the temperature of the internal coil exceeds the heat resistance of the coil insulation, and the insulation is reduced due to rapid aging. The monitoring of the top oil temperature of the transformer during long-term operation should be controlled below 85 ℃.

Internal faults of the transformer, such as short circuit between turns, short circuit between layers, and discharge of the coil to the enclosure;

Poor contact of the internal lead connector and heat generation;

The iron core is grounded at multiple points and the silicon steel sheet is short-circuited to increase the eddy current and overheat;

The leakage magnetic flux caused by the zero sequence unbalanced current and other reasons forms a closed circuit with the iron oil tank to generate eddy current and generate heat.

The contact area of the tap changer is small, the contact spring pressure is small, and the contact surface is heated due to the large contact resistance of the contact caused by oil film, pollution, oxidation and other reasons.

Especially after the tap changer is adjusted or the transformer is overloaded, the overheating phenomenon of the tap changer is likely to increase.

The transformer does not meet the conditions for parallel operation. If the capacity ratio of the two transformers exceeds 3:1, or the short-circuit impedance difference exceeds ±10%, there will be a large “circular current” between the two transformers, which will increase the temperature of the transformer oil.

This not only wastes electrical energy, but also brings greater safety hazards.

The abnormal operation or failure of the cooler, such as the shutdown of the submersible pump, the damage of the fan, the fouling of the radiating pipe, the poor cooling efficiency, and the failure of the radiator valve to open, cause the temperature to rise.

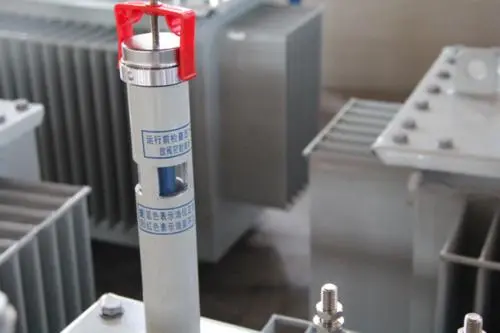

The oil level indicator reflects the oil level of the oil-immersed transformer. There is a +0 mark and +20 and -20 marks on the oil level gauge.

When the transformer is in normal operation, the float pointer in the oil conservator cannot exceed the range of ±20.

If the transformer oil temperature changes normally, but the oil level changes abnormally or unchanged, it means that the oil level is false.

(1) False oil level. During the operation of the transformer, it may be due to the blockage of the oil standard pipe, the blockage of the oil pillow respirator, the presence of air in the oil conservator or the oil pressure bag, the deterioration of the oil in the oil gauge and the moisture, the excessive or too little oil in the oil gauge, and the obstruction of the breathing plug of the oil gauge. Causes such as false oil level.

(2) The oil level is too low.

The main reasons that cause the transformer oil level to be too low are:

One is the severe oil leakage or long-term oil leakage of the transformer;

The second is that the transportation and inspection personnel did the oil sample test and did not replenish the oil after taking the oil several times;

The third is that the temperature is too low and the oil storage capacity of the oil pillow is insufficient, or the design volume of the oil pillow is too small to meet the operating requirements.

Electric Pole Transformer | Single Phase Transformer | Daelim

The external abnormalities of the transformer are mainly manifested as: the explosion-proof membrane of the explosion-proof tube, the flashover discharge of the casing, and the discoloration of the silica gel of the respirator.

One is the improper choice of explosion-proof membrane material and glass. The material has not been verified by the pressure test, and the glass has not been annealed, and the unevenness of its own internal stress causes cracks;

Second, the installation quality of the explosion-proof membrane and flange is not high, the installation process is poor when the explosion-proof membrane is installed, the force of the fastening screws is uneven, and the contact surface is inelastic, etc.;

The third is that the respirator is blocked and damaged by pressure under vacuum or nitrogen filling; the fourth is that it is damaged by external forces or natural disasters.

One is that the surface of the casing is too dirty, such as dust and dirt, which will cause the surface of the casing to reduce insulation and flashover discharge in rainy weather;

The second is that the surface of the bushing is not smooth, which causes the electric field to be uneven during operation and abnormal discharge occurs;

The third is the poor manufacture of the high-voltage bushing and the poor grounding of the end screen.

Poor welding causes damage to the insulation of the casing, the porcelain bottle mandrel of the grounded end screen is not concentric with the grounding screw sleeve, the lead of the end screen of the casing is poorly contacted or the end screen is not grounded, etc., resulting in an increase in potential and gradual damage;

Fourth, there is an internal or external overvoltage in the system, and there is a hidden danger in the bushing, which leads to breakdown.

One is that the silicone glass cover tank is cracked or damaged, and the breathing tube is not tightly sealed so that the moist air enters the silicone tank directly;

The second is that there is no oil in the oil seal cover of the lower part of the respirator or the oil level is too low, which can not function as a good oil seal, so that the moist air enters the silica gel tank directly without being filtered by the oil seal;

The third is the poor installation of the respirator, such as cracked rubber pads, loose screws for installation, and loose sealing and damp.

The transformer lead includes the inner and outer end joints of the bushing, winding joints, tap switch joints, etc.

Insufficient tightening pressure of joint connecting bolts, small contact surface, oxidation of contact surface, etc., often result in joint heating and discoloration, surface coating damage, burning damage, etc. The heating of the internal joint of the transformer may cause the gas protection action and cause the accident area to expand.

One is that the fastening part of the casing terminal is loose, and the lead wire nose is slippery;

Second, the contact surface is seriously oxidized and the contact area is small.

The above reasons make the contact area overheat, the color becomes darker and loses its luster, and the surface coating will be destroyed.

The bushing terminals and insulators are dirty or damaged. Discharge and flashover often occur in haze weather, forming voltage heating, and at the same time producing a special ozone smell.

When the transformer is overloaded or short-circuited, it often causes poor contact and overheating of poorly manufactured joints.

When the transformer oil temperature is 80-140 ℃, the life loss of transformer paper insulation doubles for every 6 ℃ increase in temperature.

When the cooling equipment fails, the operating temperature of the transformer will rise rapidly, especially in high-temperature weather or high-load operation, the life loss of the transformer insulation will increase sharply.

(1) Mechanical failure of cooling equipment.

The first is the failure of the circulating oil pump, such as the damage of the impeller of the oil pump, the disconnection of the connecting shaft, the oil leakage of the pump body, the damage of the bearing, etc., which make the oil unable to circulate or reduce the circulation speed, causing the oil temperature to rise;

The second is the failure of the fan, such as broken fan blades, disconnection of the connecting shaft, damage to the bearing, etc., which reduces the cooling air volume and causes the oil temperature to rise.

(2) Electrical failure of the cooling system.

Such as fan or oil pump motor burned out, primary circuit failure (fuse blown, poor contact or broken wire), control circuit broken wire, control element burned out, contact sticking, etc., which make the cooling system unable to work normally and cause the oil temperature to rise .

(3) The cooling system radiator is faulty.

Mainly caused by the blockage of the heat sink, the damage of the heat sink, the reduction of the area, and the coverage of foreign objects.

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

The primary function of the pad mounted transformer is to serve as a critical distribution transformer that steps down higher primary voltage from utility distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that converts high voltage electricity to lower, usable voltages for residential

When looking for the best pad-mounted transformer manufacturer, it’s important to find industry leaders known for reliability and innovative solutions. Pad-mounted transformers are essential in

After filling in the contact information, you can download the PDF.