How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

ELECTRIC, WITH AN EDGE

(1) Induction heating method. The body of the device is placed in the original fuel tank, the coil is wound around the fuel tank to pass current, and the eddy current heat of the tank skin is used to dry it. At this time, the box wall temperature should not exceed 115℃~120℃, and the body temperature should not exceed 90℃~95℃. For the convenience of winding the coil, try to make the number of turns of the coil-less or the current smaller. Generally, the current is 150A, and the wire can be 35-50mm2. Multiple asbestos strips can be placed on the wall of the fuel tank, and the wires are wound on the asbestos strip plate. The power required for induction heating depends on the type of transformer and drying conditions.

(2) Hot air drying method. Put the transformer in the drying room and put in hot air for drying. The drying room can be lapped with wall panels according to the size of the transformer body. The wall panels are covered with asbestos boards or other canvas or asbestos linen cloth impregnated with fireproof solution. The drying room should be as small as possible, and the distance between the wall plate and the transformer should not be greater than 200mm. It can be heated by an electric furnace or steam serpentine tube.

When using an electric furnace, the power consumption is calculated by the following formula: the amount of hot air passing through the drying chamber Q per minute is selected according to the volume q of the drying chamber, and generally, Q=15qm3 is used for calculation.

P≈0.07γQ(t2-t1) where P- required electric furnace power, kW γ- air constant pressure specific heat (all 0.31) t2, t1- inlet hot air temperature and ambient air temperature, ℃

When drying, the temperature of the imported hot air should gradually rise, and the maximum temperature should not exceed 95℃. A filter or metal grid should be installed at the hot air inlet to eliminate fire stars and dust. The hot air should not be blown directly to the body, but evenly blow to all parts from below the body, so that the moisture is released through the ventilation holes in the box.

(3) Vacuum drying method. This drying method uses air as the heat-carrying medium. Under atmospheric pressure, the transformer body or winding is gradually preheated to about 105°C before vacuuming is started. Due to the slow heat transfer and uneven heating inside and outside (cold inside and outside heating), high-voltage and large-capacity transformers often require more than 100 hours of preheating due to the thick insulating layer. The production cycle is very long, and the drying is not thorough. It is difficult to meet the insulation requirements of transformers. But the equipment is simple and easy to operate.

(4) Gas-phase vacuum drying method. This drying method uses a special kerosene vapor as the heating medium, and the kerosene vapor introduced into the vacuum tank is condensed on the transformer body and releases a large amount of heat energy, thereby heating the body of the dryer. Due to the large heat energy of kerosene vapor (the heat of kerosene gasification is 306×103j/kg), the transformer body can be dried and heated more thoroughly, more uniformly, with high efficiency, and the damage to the insulating material is also small. However, due to its complex structure and high cost, it is currently only used in the drying treatment of large transformer bodies of 110kV and above.

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

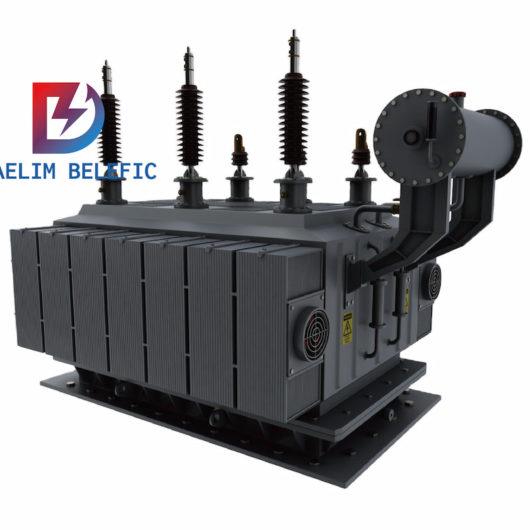

The primary function of the pad mounted transformer is to serve as a critical distribution transformer that steps down higher primary voltage from utility distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that converts high voltage electricity to lower, usable voltages for residential

When looking for the best pad-mounted transformer manufacturer, it’s important to find industry leaders known for reliability and innovative solutions. Pad-mounted transformers are essential in

After filling in the contact information, you can download the PDF.