sbi crypto mining

What is sbi crypto mining? sbi crypto mining is a division of Japan’s SBI Holdings

ELECTRIC, WITH AN EDGE

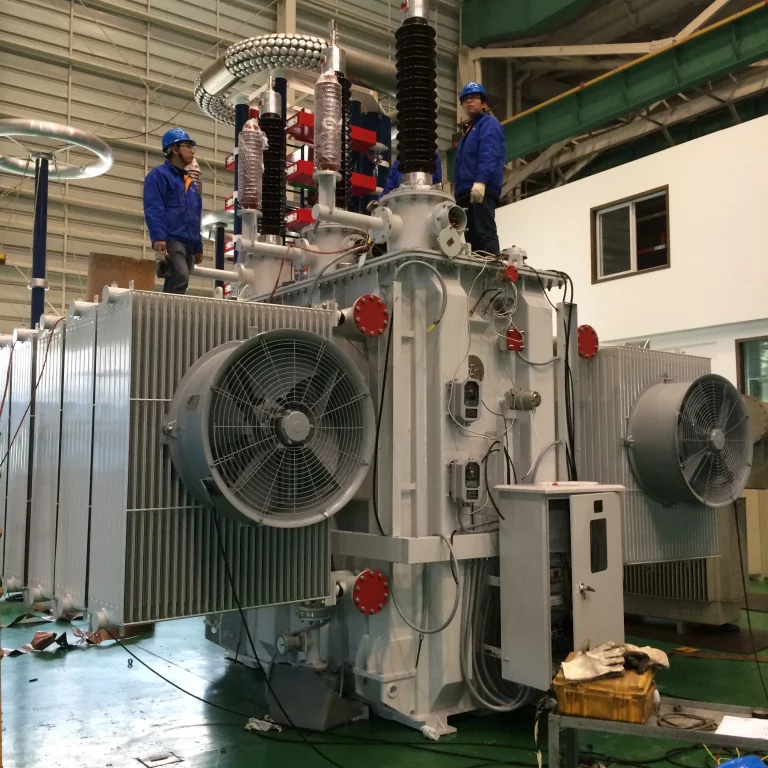

Se ha explorado el uso de transformadores principales de alta capacidad en la construcción de subestaciones en zonas de rápido crecimiento de carga y fuerte concentración, y se ha trabajado en la selección de parámetros de transformadores de alta capacidad. En este trabajo se realiza una comparación técnica y económica de la capacidad del transformador principal de 360 MVA o 240 MVA en la subestación. Se concluye que al utilizar un transformador principal de 220 kV y 360 mva, la subestación puede ahorrar un 5 % de la inversión en equipos y aproximadamente un 14 % del espacio de piso, al tiempo que reduce la carga de trabajo de operación y mantenimiento, etc.

Los resultados reales de la operación muestran que el equipo está funcionando bien y que todos los parámetros de rendimiento están dentro del rango de diseño.

Actualmente no existen barreras técnicas para el transformador reductor trifásico de alta capacidad de 220 kV y 360 MVA para generadores de Daelim, que se puede fabricar de acuerdo con las normas EHV y las normas IEC pertinentes.

Desde el punto de vista de la fabricación, los transformadores Daelim no tienen ningún problema con la elevación y la prueba de toda la unidad, y las piezas grandes se pueden transportar por agua, tierra o ferrocarril.

El transformador de 220 kV 360 MVA fabricado por Daelim se encuentra actualmente en operación en áreas con alto crecimiento y concentración de carga.

Los resultados muestran que el equipo funciona bien y que todos los parámetros están dentro del rango de diseño. La experiencia en diseño y construcción se puede utilizar como referencia para la aplicación de transformadores de 360 MVA y 220 kV de mayor capacidad en la red.

De acuerdo con el contenido de selección del transformador principal en el diseño general y las especificaciones del equipo de las empresas de la red eléctrica correspondientes, la capacidad máxima del transformador principal para las subestaciones de 220 kV se puede seleccionar como 240 MVA.

Ciertas empresas de generación de energía y usuarios industriales de acero y aluminio tienen una pequeña cantidad de transformadores con una capacidad de 300 MVA en operación, pero estos se limitan a transformadores de doble volumen, que son diferentes de los transformadores reductores de generador de tres volúmenes comúnmente utilizado en las redes eléctricas.

Los transformadores principales de 360 mva en las subestaciones de 220 kV siguen siendo principalmente de 180 MVA y 240 MVA de capacidad. Sin embargo, los transformadores de 360 MV/220 kV pueden reducir mejor el área utilizada en las subestaciones y reducir los costos de construcción y operación.

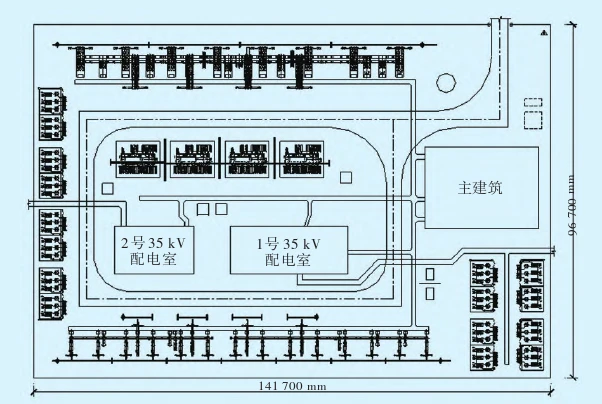

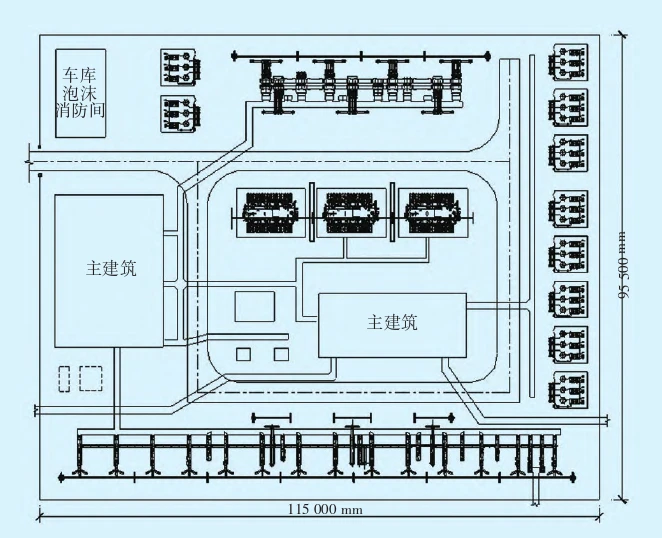

Con el fin de analizar las ventajas y desventajas de los transformadores principales de 360 MVA, este trabajo ha diseñado dos esquemas preliminares para las subestaciones, el esquema 1 escala de construcción del transformador principal es de 4 x 240 MVA; La escala de construcción del transformador principal del esquema 2 es de 3 x 360 MVA.

Ambas opciones utilizan equipos GIS de exterior para distribución de 220 kV y 110 kV, con el mismo número de circuitos de salida y la misma escala de distribución de 35 kV y otras instalaciones en la estación.

(Plan eléctrico general del esquema 2 la capacidad de un solo transformador principal es de 360 MVA)

Comparando las dos opciones, la superficie de la subestación se ahorra alrededor de un 15 % en comparación con la opción 2 porque la opción 1 reduce la cantidad de transformadores principales y la cantidad de intervalos de entrada triple del transformador principal, intervalos seccionales e intervalos de equipo de barra colectora.

La capacidad total de los transformadores principales de la subestación en las dos opciones anteriores es de 1080 MVA y 960 MVA respectivamente, con la Opción 2 aumentando la capacidad de suministro de energía en 120 MVA en comparación con la Opción 1. Ambas opciones resuelven el problema de los puntos de aterrizaje para la subestación de 110 kV en la región, y las funciones y ubicación de la subestación son básicamente las mismas y comparables en términos de aspectos técnicos y económicos.

En términos de inversión básica comparativa del proyecto, el costo total de la Opción 2 es 5% menos que el de la Opción 1.

Los costos de adquisición de terrenos para la Opción 2 son aproximadamente un 14 % inferiores a los de la Opción 1.

En términos de los principales costos de equipos eléctricos primarios y las inversiones en cimientos de equipos correspondientes, el número de intervalos de entrada del transformador principal para cada nivel de voltaje en la Opción 2 es menor que en la Opción 1.

Por lo tanto, con la excepción de los costos del transformador principal, todos los demás costos de equipo son más bajos en la Opción 2 que en la Opción 1.

Además, la Opción 2 tiene un transformador principal menos que la Opción 1, y las instalaciones de protección contra incendios del transformador principal en toda la estación (por ejemplo, el sistema de rociado de agua del transformador o el sistema de extinción de incendios con espuma) se han reducido en consecuencia.

De manera similar, el sistema de protección del transformador principal, el dispositivo de monitoreo en línea de cromatografía de aceite y el uso del cable secundario correspondiente se reducen en consecuencia, se reduce la cantidad de instalaciones auxiliares relacionadas con el transformador principal y también se reduce la carga de trabajo de mantenimiento del equipo después de la puesta en servicio. respectivamente.

De acuerdo con los requisitos y la planificación de la red regional, las tensiones del transformador para alta, media y baja tensión se establecen en 220 kV, 110 kV y 35 kV, con capacidad total (es decir, 360 MVA) utilizada para alta y media tensión.

Teniendo en cuenta el papel y la función de los transformadores de alta capacidad en la red, no se recomiendan los transformadores divididos para el lado de baja tensión del transformador de 220 kV y 360 MVA.

El uso de transformadores divididos en el lado de BT, aunque es eficaz para reducir el ciclo de trabajo de los devanados individuales, aumentaría el tamaño total del transformador y representaría un riesgo para la fabricación y el transporte.

Al mismo tiempo, cuando 1 de las ramas sufre un cortocircuito fuera de servicio, la resistencia de cortocircuito de la otra rama se reducirá considerablemente y el transformador dividido no es propicio para un funcionamiento seguro y estable.

Por lo tanto, la capacidad del lado de baja tensión se elige para configurarse de acuerdo con 1/3 de la capacidad del transformador principal, es decir, 120 MVA, lo que permite que la capacidad de salida de conmutación del lado de baja tensión no esté restringida sin afectar la resistencia de cortocircuito del transformador. transformador principal.

El transformador de 220 kV 360 MVA estudiado en este trabajo está restringido por el plan de red regional y el grupo de acoplamiento es del tipo YN/yn0/yn0, sin devanados triangulares en el transformador.

En este caso, es una práctica común agregar un devanado de equilibrio adicional de 10 kV al transformador. El devanado de equilibrio está cableado triangularmente y, por lo general, no emite energía externa, pero principalmente proporciona un camino para la corriente del tercer armónico, eliminando el flujo del tercer armónico y, por lo tanto, el componente del tercer armónico del voltaje.

La configuración de la capacidad del devanado de equilibrio se basa en la experiencia del devanado de equilibrio en los transformadores, el modo de operación y la forma estructural del devanado de equilibrio.

Al mismo tiempo, se combinan las opiniones de los distintos fabricantes para asegurar que el transformador pueda cumplir con los requisitos de uso, cuando actúa solo como devanado de equilibrio, y generalmente está diseñado para una clase de 10 kV con una capacidad de aproximadamente 1/ 3 de la capacidad nominal del transformador.

Por lo tanto, la capacidad del devanado de equilibrio del transformador de 220 kV y 360 MVA que se estudia en este documento se establece en 120 MVA.

En resumen, una relación de capacidad de transformador razonable es 360 MVA/360 MVA/120 MVA+120 MVA (capacidad de devanado de equilibrio de 10 kV) cuando los tres lados del transformador son 220 kV, 110 kV y 35 kV respectivamente; la elección final del grupo de acoplamiento es el tipo YN/yn0/yn0+d.

En la actualidad, los métodos de enfriamiento comunes para los transformadores de 220 kV y 360 MVA son el autoenfriamiento sumergido en aceite, el enfriamiento por aire sumergido en aceite, el enfriamiento por aire con circulación forzada de aceite y el enfriamiento por agua con circulación forzada de aceite.

Las siguientes son soluciones específicas para el método de enfriamiento adecuadas para transformadores de 220 kV 360 MVA

(1) Método de autoenfriamiento de circulación de aceite natural: Como la capacidad del transformador principal utilizado en este caso es demasiado grande, el volumen del radiador externo del transformador de autoenfriamiento excederá los lados del cuerpo por mucho y la estructura es irrazonable, por lo tanto, los fabricantes no recomiendan el método de autoenfriamiento de circulación de aceite natural.

(2) Método de refrigeración por aire con circulación de aceite natural: tiene las características de una tecnología madura y un funcionamiento estable. Cuando se usa este método, el nivel de ruido del transformador se puede controlar por debajo de 70 dB, el mínimo se puede controlar a 65 dB (pero el costo aumentará).

(3) Forma refrigerada por aire de circulación forzada de aceite: la estructura del cuerpo del tanque de aceite es más compacta y razonable, el tamaño de la forma es más pequeño, fuerte resistencia a los cortocircuitos; pero aumenta la tasa de fallas y la carga de trabajo de operación y mantenimiento, debe usar una bomba de aceite de mejor calidad; el nivel de ruido del transformador solo se puede controlar a 75 dB.

El sistema de enfriamiento por aire de circulación forzada de aceite de transformadores sumergidos en aceite es el sistema de enfriamiento surgido en la década de 1990, con requisitos de alta confiabilidad de la fuente de alimentación en funcionamiento, el rendimiento de autoenfriamiento del sistema de enfriamiento es bajo, mantenimiento y reparación, consumo de energía y alto nivel de ruido. Si falla el sistema de refrigeración por aire, provocará un apagado por sobrecarga del transformador, lo que afectará el funcionamiento seguro de la red y el suministro de energía confiable.

El sistema de refrigeración por aire de refrigeración natural/circulación de aceite natural del transformador sumergido en aceite tiene las ventajas de un buen rendimiento de auto refrigeración, bajo mantenimiento, bajo consumo de energía y ruido, etc., y por lo tanto es ampliamente utilizado.

Con base en el análisis anterior, se recomienda que el transformador principal de 220 kV y 360 mva se enfríe con aire de circulación natural de aceite.

Para parámetros como pérdidas, ruido y aumento de temperatura del transformador, los valores recomendados para los principales parámetros técnicos del transformador de 360 MVA/220 kV se obtuvieron combinando las opiniones de todas las partes, teniendo en cuenta la economía y la practicidad, y tomando como referencia a los parámetros del transformador principal de 360 MVA/330 kV que ya se ha aplicado con madurez.

Download Resource

What is sbi crypto mining? sbi crypto mining is a division of Japan’s SBI Holdings

In this paper, the authors will comprehensively analyze the development process of the pad mounted