ELECTRIC, WITH AN EDGE

In the heart of an industrial zone in America, a powerhouse hums with energy, its lifeblood coursing through an unseen network. At its core lies a 1500 kVA transformer, an unsung hero in the world of power distribution. This might seem just a regular piece of equipment, yet it’s crucial in energizing countless industries across the nation. Imagine this: a single 1500 kVA transformer can efficiently power up to 1200 average American homes. But in this context, it’s the driving force behind machines that mould, cut, and shape the future.

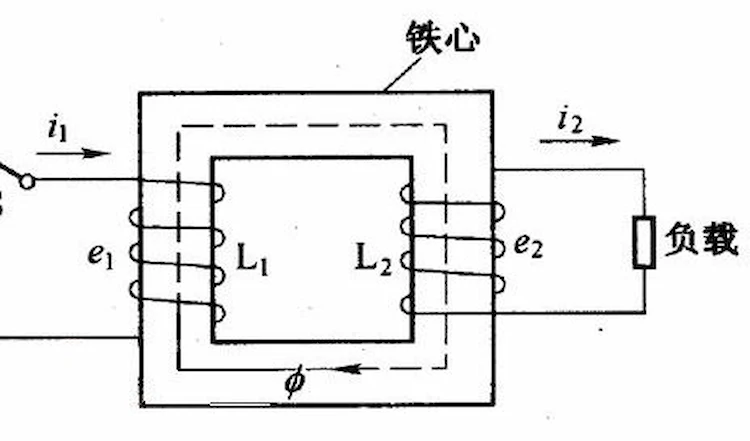

Transformers are vital components in the electrical grid, serving as guardians and arbiters of power. They perform the critical task of stepping up or down the voltage levels, ensuring that electricity is delivered at the right voltage for various applications. Without them, the risk of overloads and inefficiencies would be a constant threat.

In this exploration, we delve into the world of 1500 kVA transformers, uncovering their key specifications, applications, and the crucial role they play in keeping American industries running smoothly.

Pofessional Manufacturer of Pad Mounted Transformer Substation Transformer,HV Power Transformer Single Phase Transformer IEEE/ANSI,CSA,DOE,AS/NZS,IEC and etc。standards

Importantly, how do you choose a 1500 kva transformer that is right for you?

Read on to learn everything you need to know about 1500 kva transformers.

Then we will show you specific cases.

First of all, we make sure that a transformer with a rated capacity of 1500kva must not be a power transformer, but a distribution transformer.

The distribution transformers can be divided into two types according to the insulating medium: oil-immersed transformers and dry-type transformers.

Our common 35kv class three-phase oil-immersed transformer, 20kv class three-phase oil-immersed transformer and 10kv class three-phase oil-immersed transformer can all reach rated power of 1500kva.

At the same time, the 35kv three-phase epoxy resin dry-type transformer, the 20kv three-phase epoxy resin dry-type transformer, and the 10kv three-phase epoxy resin dry-type transformer can also achieve a rated capacity of 1500kva.

After deciding whether you need to buy a dry-type transformer or an oil-immersed transformer, let’s find out:

What factors can affect the life of a transformer?

There are many factors that affect the life of a transformer.

The temperature and humidity of the environment, the frequency of use of the transformer, the load power of the transformer, the quality of the raw material of the transformer, and the aging degree of the insulating material will affect the life of the transformer.

Example: The effect of temperature and humidity on transformers.

Experiments show that the insulation temperature is high, the aging accumulation is high, and the mechanical loss cannot be recovered, which is very harmful to the life.

The local temperature rises, the transformer temperature is high, and the life is short.

According to experience, the hottest temperature of the transformer is at the upper 2/3 of the winding stack and 1/3 of the high-voltage winding, and the heat is about 2/3 of the equal winding. For a running transformer, it will change the oil flow distribution inside the transformer and The temperature distribution leads to an increase in temperature, and the electrostatic discharge generated by the charging process of the oil flow in the transformer is most likely to occur in the dense area of space charge.

For example, near the inlet of the oil passage in the lower part of the winding and the outlet of the oil passage in the upper part of the winding, the power frequency field strength of these parts is very weak.

Therefore, the discharge depends entirely on the electrostatic potential generated by the accumulation of space charges, and the tolerance of the medium, and has the characteristics of discharge under a DC electric field. The discharge repetition rate is low, and the time from discharge initiation to accident is long.

Therefore, some signs of discharge can be found through monitoring, but sometimes discharge can also occur in oil passages or other parts with high working field strength.

Therefore, the cooling of the exhaust air of the transformer working on site must be done well, so that the main body is not overheated, and the ambient temperature should be monitored well.

Secondly, the drying time of vacuum drying furnace should be sufficient for components such as insulating cardboard.

Third, the transformer in operation should be closely monitored. If the indicators are abnormal, it should be dealt with. If the water in the oil is large, use a vacuum oil filter to filter the oil. If the medium loss is large, it needs to be adsorbed and filtered by white clay.

If the problem is particularly serious, it should be returned to the manufacturer for comprehensive treatment, including lifting the core, vacuum filtration of insulating oil, and drying of the body in a vacuum tank.

irst, according to the electrical load calculation formula:

Sn=Pjs/(β*cosΦ)

Pjs——active computing load (kW);

cosφ power factor;

β–transformer load utilization factor;

Sn=Pjs/(β*cosΦ)=1500/(0.85*0.9)=1960KVA

For 1960KVA, you can choose the common 2000kva transformer on the market.

Although there is also a transformer in the switching power supply, its oscillation frequency is very high, the volume and weight are relatively small, and the efficiency is very high. Other electronic components such as switching tubes and rectifiers consume little power.

When two 630kVA units are connected in parallel, the ideal maximum output is 2*630=1260kVA. The load rate of the transformer is also required to be 80%, which means that the transformer capacity can only be used at 1260*0.8=1008kVA.

The power factor is calculated as 0.9. At this time, the maximum output active power of the transformer is 1008*0.9=907.2kW<(1500+250=)1750kW.

This capacity needs to be larger than the capacity of the 1500 kva transformer. Usually, it is designed to be used normally at 2000 kVA immediately, and it can also be used normally if the load is added later.

Next, I will tell you in detail:

This is a purchasing manager for a cryptocurrency farm from Canada.

The other party is very puzzled at first, is daelim a manufacturer?

Daelim’s sales engineer showed him the relevant certificates of IEC, ANSI/IEEE, CSA and AS obtained by Daelim’s factory. This is something a dealer wouldn’t have.

Special CSA certificate, which is a prerequisite for entering the Canadian market.

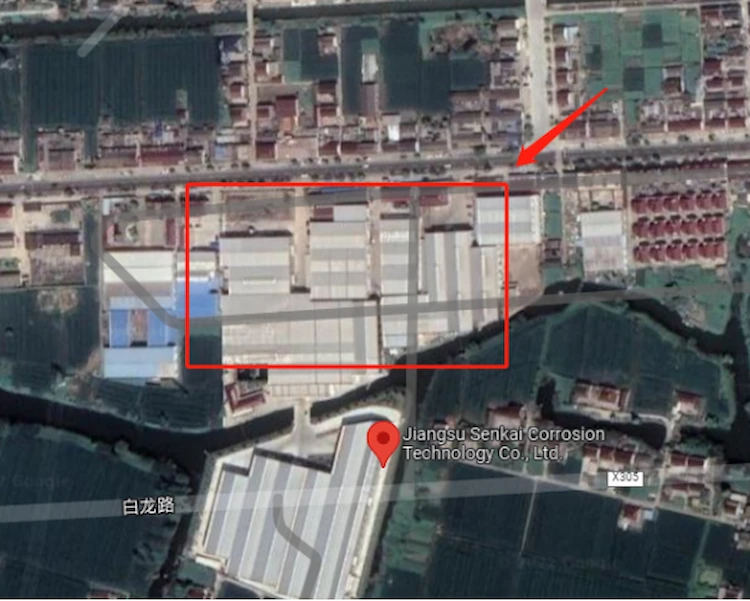

At the same time, Daelim also told the other party that the other party is always welcome to assign a third party to Dalin’s factory in Jiangsu for inspection.

DAELIM: For normal transformers, our standard production time is 4-6 weeks, for customized transformers, our fastest production time is 6-8 weeks.

The most important thing is that the other party asked:

DAELIM: Because our factory located in the transformer base in China, we have well raw material supply chain. So we can always provide the competitive price to our customers.

Pole mounted up to 167kva and Pad mounted up to 1500kva.

Quantities: 357 sets.

This project has 357 transformers, a total of 20 different items. DAELIM need detailed design for each items. Daelim was asked to provide production drawings within three weeks.

Due to the project needs of end users, the production time of transformer is only 90 days. But DAELIM’s production line is full at that time because other customers order.

The single-phase transformer needs to meet the standards of CSA 2.1 and CSA 2.2, pad mounted transformer needs to meet the standards of CSA 227.4, and the design of transformer parts and marks of transformers need to customize production.

In order not to affect the delivery time, DAELIM engineer team delivered the drawings in batches. 60% of the drawings were delivered within two weeks and production was arranged in time. The remaining drawings were successfully delivered in the remaining two weeks.

DAELIM’s management pay much attention to the needs of customers, and has communicated with the production team and our supplier team for many times. The workers worked overtime to ensure the delivery of the customer requests.

Our team of engineers studied the CSA Standard carefully. Because they are based on IEEE standard, DAELIM designed and produced them according to it. For the existing technical problems or difference, our team has carried out hundreds of e-mail and telephone communication with customers .

Ultimately, Daelim completed production within 90 days. And provide pictures to each other after the production is completed.

When finish the production, DAELIM did above FAT tests for each transformer one by one, and submit the testing report in time.

1. Ratio, Polarity, and Phase Relation

2.Resistance

3.Applied Potential

4.Induced Potential

5. Loss Test

6. Leak Test

7. Operation tests of all devices

For single phase transformer, we used the wooden frame structure for the capacity up to 50kva, so it will save space and sea shipping cost.

For 1500 kva pad mounted transformer, we used the wooden pallet packing design, the customers can easy to take out the pad mount transformer from container.

Download Resource

After filling in the contact information, you can download the PDF.