ELECTRIC, WITH AN EDGE

A pad mounted transformer is a specialized ground-mounted distribution transformer that serves as a critical component in electrical power distribution systems. Housed in a locked metal cabinet and situated on a concrete pad, these transformers efficiently step down high voltage from utility lines to levels suitable for residential and commercial use. Their unique enclosed design eliminates the need for protective fencing, making them ideal for residential areas while maintaining optimal safety standards.

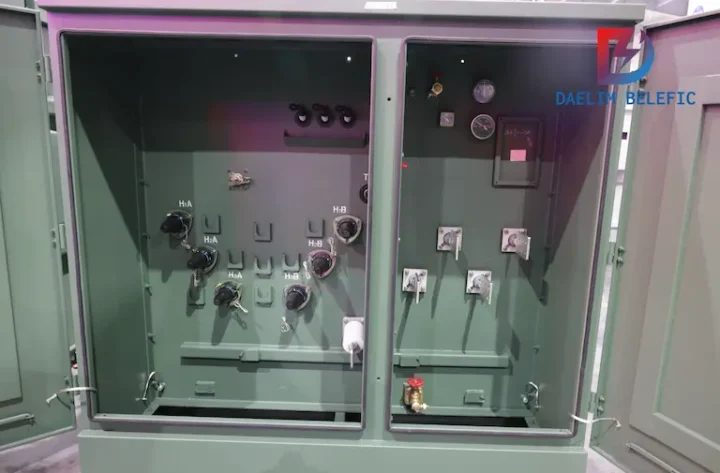

These transformers typically operate within power ratings of 75 to 5000 kVA, featuring a robust design that includes an oil-immersed core/coil assembly and separate compartments for high and low voltage connections. The secure metal enclosure houses all live electrical components, ensuring safe operation in populated areas while providing reliable power distribution to multiple residences or large commercial buildings.

A key feature of pad mounted transformers is their connection to underground utility distribution lines through service drops. This configuration enables them to effectively transform primary voltage from utility lines to secondary voltage levels appropriate for end users. The transformation process occurs within the specially designed tank, where the core/coil assembly remains immersed in insulating oil for optimal performance and safety.

The construction of these transformers prioritizes security and durability. The main enclosure consists of a welded tank containing the core/coil assembly, complemented by a wiring cabinet with distinct compartments for high and low voltage connections. Access to these components is controlled through lockable doors that swing outward, allowing maintenance while maintaining safety protocols.

For safe implementation, specific location guidelines must be followed. These requirements, based on insurance industry recommendations, govern the placement of transformers in relation to building structures. Property owners must verify compliance with local inspection authorities and insurance carriers regarding acceptable transformer locations, as proximity restrictions may apply to building components.

The practical installation process demands careful attention to detail. The concrete pad must be properly prepared and leveled to support the transformer’s weight. Additionally, the installation location must allow adequate access for maintenance while maintaining safe distances from buildings and other structures. Regular maintenance procedures include inspection of seals, monitoring of oil levels, and verification of proper grounding systems.

Understanding the operational aspects of pad mounted transformers is essential for facility managers and property owners. While only qualified personnel should access the internal components, knowledge of basic safety protocols and emergency procedures ensures proper response to potential issues. This includes maintaining clear documentation of utility contacts and service procedures.

The implementation of pad mounted transformers requires coordination with local utilities and compliance with electrical codes. Professional installation by qualified electricians ensures proper connection to underground service lines and appropriate grounding. Regular inspection schedules and maintenance protocols must be established to maintain safe and reliable operation throughout the transformer’s service life.

Read more about the pad mounted transformer.

After filling in the contact information, you can download the PDF.