How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

ELECTRIC, WITH AN EDGE

1. At present, most dry-type transformers use H-class insulating materials, so generally the temperature of dry-type transformers should be below 180°C.

2. When class A insulating material is used, the maximum transformer temperature rise should be less than 60K when its limit working temperature is 105℃; when class E insulating material is used, the maximum transformer temperature rise should be less than 75K when its limit working temperature is 120℃;

3. When using Class B insulating materials, the maximum temperature rise should be less than 80K when the limit operating temperature is 130°C;

4. When using Class C insulating materials, the maximum temperature rise should be less than 150K when the limit working transformer temperature is 220℃.

5. When using Class F insulating materials, the maximum temperature rise should be less than 100K when the limit working temperature is 155℃;

6. When using Class H insulating materials, the maximum temperature rise should be less than 125K when the limit operating temperature is 180°C.

Under no circumstances should there be a transformer temperature that damages the core itself, other parts or materials adjacent to it.

Most dry-type transformers use H-class insulating materials, so it is generally said that the temperature of dry-type transformers should be below 180°C.

The transformer temperature at which dry-type transformers will alarm, dry-type transformers generally will alarm at 130°C.

Most dry-type transformers use H-class insulation materials. When the transformer is in normal operation, its thermostat control settings are generally: 80 ℃ automatically turn off the fan, 100 ℃ automatically open the fan, 130 ℃ high temperature alarm, 150 ℃ ultra-high temperature trip.

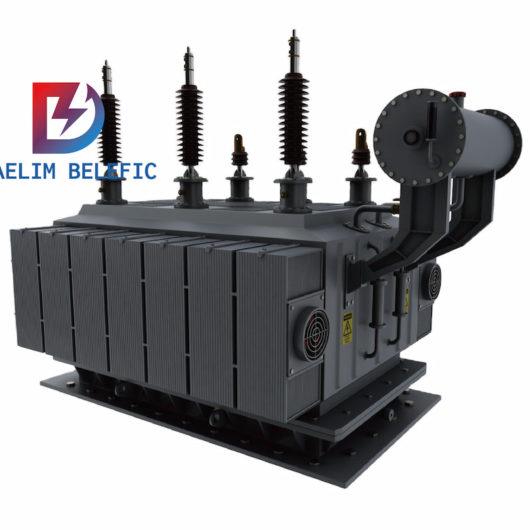

What’s The Difference Between Dry-Type And Oil-Immersed Transformers

In dry-type transformers, there are two cooling methods, one is natural air cooling (AN), and the other is forced air cooling (AF).

When natural air cooling, the transformer can run continuously for a long time under the rated capacity. When forced air cooling, the output capacity of the transformer can be increased by 50%.

It is suitable for intermittent overload operation or emergency accident overload operation; load loss and impedance voltage increase greatly when overloaded, and it is in a non-economic operation state. It is necessary to avoid long-term continuous overload operation.

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

The primary function of the pad mounted transformer is to serve as a critical distribution transformer that steps down higher primary voltage from utility distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that converts high voltage electricity to lower, usable voltages for residential

When looking for the best pad-mounted transformer manufacturer, it’s important to find industry leaders known for reliability and innovative solutions. Pad-mounted transformers are essential in

After filling in the contact information, you can download the PDF.