How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

ELECTRIC, WITH AN EDGE

10kv class distribution transformers are widely used on the high-voltage side of the drop-out fuse. Practice has proved that this is an economical, simple and effective method. The drop-out fuse can disconnect the power supply when there is a fault inside the 10kv class distribution transformer, and it is also convenient for the normal operation of the 10kv class distribution transformer. In addition, the price is cheap, the structure is simple, and the installation is simple. It can be used as an isolation switch and overload and short circuit protection. Because it has an obvious disconnection point, it has the function of an isolation switch, creating a safe operation for the lines and equipment in the maintenance section. environment, which increases the safety of maintenance personnel.

The drop fuse consists of three parts: a porcelain insulator, a contact conductive system and a fuse tube. During normal operation, the fuse locks the movable joint on the fuse tube, and the fuse tube is in a closed state under the pressure of the upper contact. In the event of a fault, the fuse is blown, and an arc is generated in the fuse tube. The arc suppression tube lined with the fuse tube decomposes a large amount of gas under the action of the arc, and produces a strong deionization effect when the current crosses zero to extinguish the arc. The fuse is broken, so the release of the movable joint makes the fuse tube sag, and it falls rapidly under the action of the elastic force of the upper and lower contacts and the self-weight of the fuse tube, forming an obvious disconnection gap.

First of all, the short-circuit capacity of the installation site should be within the rated breaking capacity of the drop-out fuse. If it exceeds the upper limit, the fuse tube may explode due to excessive current and excessive gas production; if it is lower than the lower limit, it is possible The arc cannot be extinguished because the current is too small and the gas production is insufficient.

Therefore, when selecting the rated capacity of the drop-out fuse, it is necessary to consider that its upper limit breaking current matches the maximum short-circuit current of the installation site, and also pay attention to the relationship between its lower limit breaking capacity and the minimum short-circuit current of the installation site.

Considering that the drop-type high-voltage fuse is used as an internal fault of the distribution transformer of 10kv class, the protection range is from the side of the low-voltage fuse 10kv class distribution transformer to the side of the high-voltage fuse 10kv class distribution transformer, and it is also used as a backup for the low-voltage fuse. For protection, the lower limit breaking capacity should be selected with the two-phase short circuit at the low-voltage outlet as the minimum value of the short-circuit current.

When choosing a fuse, pay attention to the upper and lower limits of its rated breaking capacity, not the larger the rated breaking capacity, the better.

(1) The melt should be tightened during installation (the melt is subject to a tensile force of about 24.5N), otherwise it is easy to cause the contact to heat up.

(2) The fuse installed on the cross arm (frame) should be firm and reliable, and there should be no shaking or shaking.

(3) The melting tube should have a downward inclination angle of 25°±2°, so that the melting tube can quickly fall by its own weight when the melt is blown.

(4) The fuse should be installed on the cross arm (frame) with a vertical distance of not less than 4m from the ground. If it is installed above the distribution transformer of 10kv class, it should be kept at a level of more than 0.5m with the outermost contour boundary of the distribution transformer. distance, in case the melting tube falls and causes other accidents.

(5) The length of the melting pipe should be adjusted moderately, and it is required that the duckbill tongue can hold more than two-thirds of the length of the contact after closing, so as to avoid the misoperation of self-falling during operation, and the melting pipe should not hit the duckbill. , in order to prevent the melting tube from falling in time after the melt is blown.

(6) The melt used must be a standard product of a regular manufacturer and have a certain mechanical strength. Generally, the melt is required to withstand a tensile force of at least 147N or more.

(7) The 10kV drop-out fuse is installed outdoors, and the phase-to-phase distance is required to be greater than 70cm.

The rated current of the fuse should be greater than or equal to the rated current of the fuse, and the rated current of the fuse-link can be selected as 1.5-2 times the rated load current.

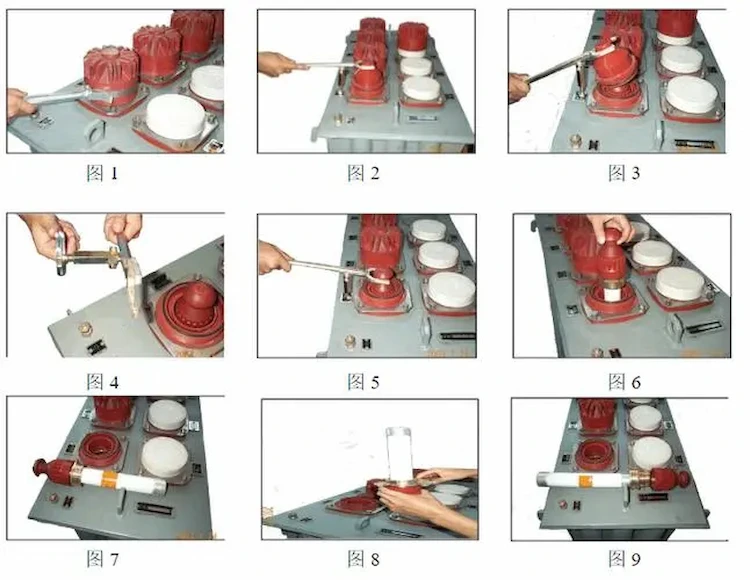

(1) The operation shall be carried out by two persons (one person to monitor and one person to operate), but must wear qualified insulating gloves, insulating boots, goggles, and use qualified insulating rods with matching voltage levels. Operation is prohibited in heavy rain.

(2) During the operation of the gate, it is generally stipulated that the middle phase is pulled off first, then the leeward side phase is pulled, and finally the windward side phase is pulled off. This is because the 10kv class distribution transformer is changed from three-phase operation to two-phase operation, and the arc spark generated when the intermediate phase is broken is the smallest, which will not cause short-circuit between phases.

The second is to break the leeward side phase, because the middle phase has been pulled apart, and the distance between the leeward side phase and the windward side phase has doubled, so that overvoltage is generated, and the possibility of short circuit between phases is also very small. When the windward phase is finally broken, there is only a capacitive current to the ground, and the spark generated is very slight.

(3) When closing, the operation sequence is reversed when closing, first close the windward side phase, then close the leeward side phase, and finally close the middle phase. Maintenance of drop-out fuses

The following matters should be paid attention to in normal operation and maintenance: whether the contact of each conductive part is intact and tight, whether the fuse tube and fuse are damaged or deformed by moisture; whether the installation angle is correct, and whether the casting and cutting operations are flexible;

Whether the porcelain insulator is damaged; in operation, the number of fuse actions must be carefully grasped (recorded), and the inner diameter of the fuse tube has been expanded to the allowable limit size due to too many actions. Tubes should be replaced in a timely manner.

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

The primary function of the pad mounted transformer is to serve as a critical distribution transformer that steps down higher primary voltage from utility distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that converts high voltage electricity to lower, usable voltages for residential

When looking for the best pad-mounted transformer manufacturer, it’s important to find industry leaders known for reliability and innovative solutions. Pad-mounted transformers are essential in

After filling in the contact information, you can download the PDF.